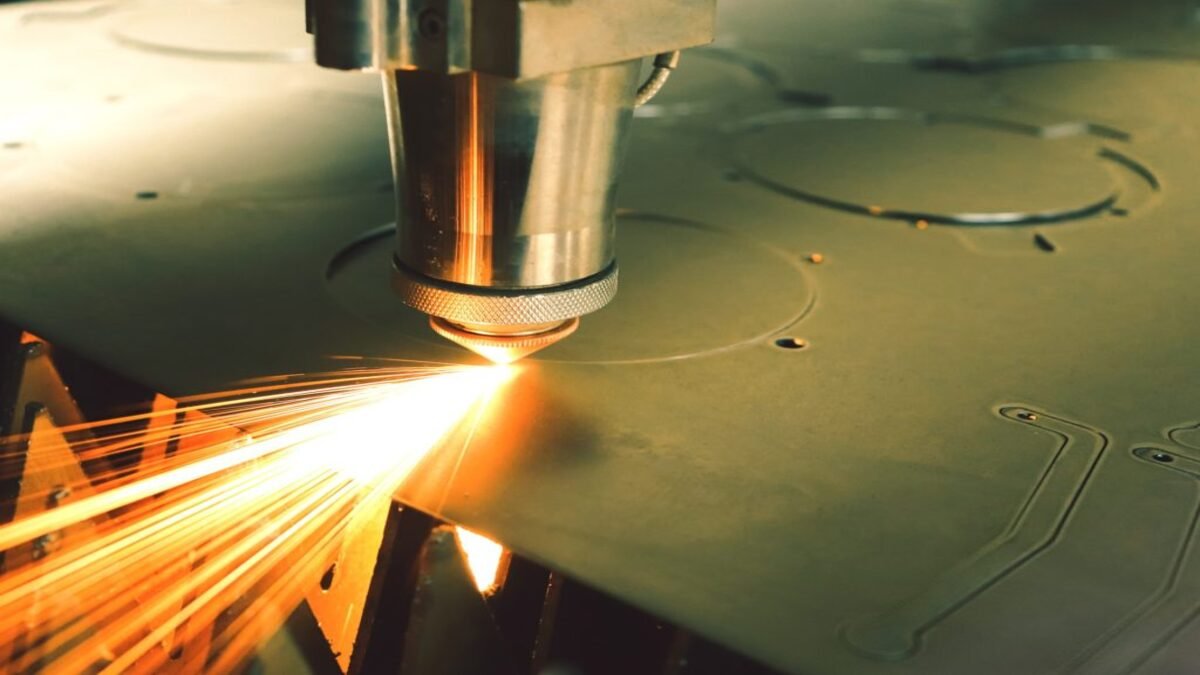

Individuals often want to know which laser cutting machine will best serve their business. Answering this question requires understanding cutting technology options, the different types of lasers, and what people typically use each laser for.

The laser beam serves as the principal component of the machine. It determines the power and wavelength along with which materials the machine can cut. Three main laser options remain available today. Learn these basics and read reviews from customers to get a better understanding of which machine is right for your organization.

Material Considerations

Before researching laser cutting machine options, determine which materials the machine will cut. This plays a role in the purchasing process, as many machines remain limited in terms of the materials they can handle. Having this information makes it easier to narrow the choices.

Solid-State Lasers

Solid-state lasers served as one of the earliest laser technologies. The machines use a glass or crystalline rod to create the necessary energy states. Diode lasers and Nd:YAG lasers fall into this category. Businesses looking to make small quantities of non-metal engravings find this machine meets their needs. Nd:YAG lasers, in contrast, aren’t appropriate for non-metal engraving, as the wavelength produced from this type of machine isn’t easily absorbed by non-metals. However, they work well for metal engraving and can produce large quantities effortlessly.

Fiber Lasers

Many metal-cutting businesses today turn to fiber lasers. A type of solid-state laser, a fiber laser operates with the help of semiconductor laser diodes. Thanks to the high surface-area-to-volume ratio of the fiber, this machine supports high output power. The high ratio allows for efficient cooling, making the high output power possible. Businesses use this machine to cut and engrave metal, but it isn’t suitable for non-metals other than engineering plastics with a resin base. This machine comes with a higher price tag, yet many businesses find this machine is ideal for their business thanks to the speed and high optical quality.

CO2 Lasers

A carbon dioxide or CO2 laser operates by running electricity through a tube filled with gas. This process produces light to carry out the desired task. Among the first gas lasers developed, CO2 lasers work with most organic materials. This includes wood, paper, rubber, glass, anodized aluminum, and more. Buyers must recognize 50W machines running at full power cannot cut materials with a metal point above 300 degrees Celsius. However, the machine can mark these materials when they come with a special coating. Higher powered CO2 lasers, those offering 1000W or more, cut metal along with other materials. Businesses find the results obtained with a CO2 laser are better than those seen with other laser options. Furthermore, the results are more precise.

Additional Questions

Consider all options when purchasing a laser machine for your business. Furthermore, be sure to learn more about what the manufacturer includes in the purchase price. For instance, what type of warranty comes with the machine? Does it include parts and labor? Will the business handle delivery and installation or does the seller oversee this task? These answers often help a business decide which machine to invest in.

Don’t let this task overwhelm you. If you need help to determine which machine is appropriate, ask the sales staff. Staff members gladly assist customers in finding a laser cutter, as they enjoy showing what their machines can do today.